machining surface finish symbols triangle

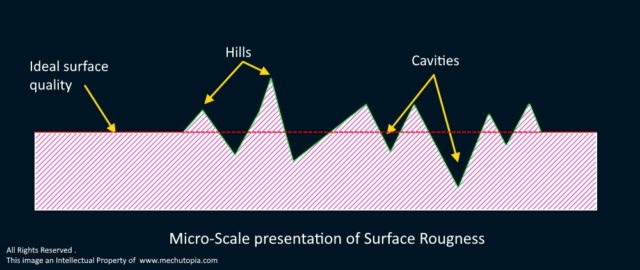

The plastic surface finish chart is a guide to the various finishes that can be applied to plastic parts. Roughness is the most commonly specified measured and calculated.

What Is Surface Finish And Surface Roughness Extrudesign

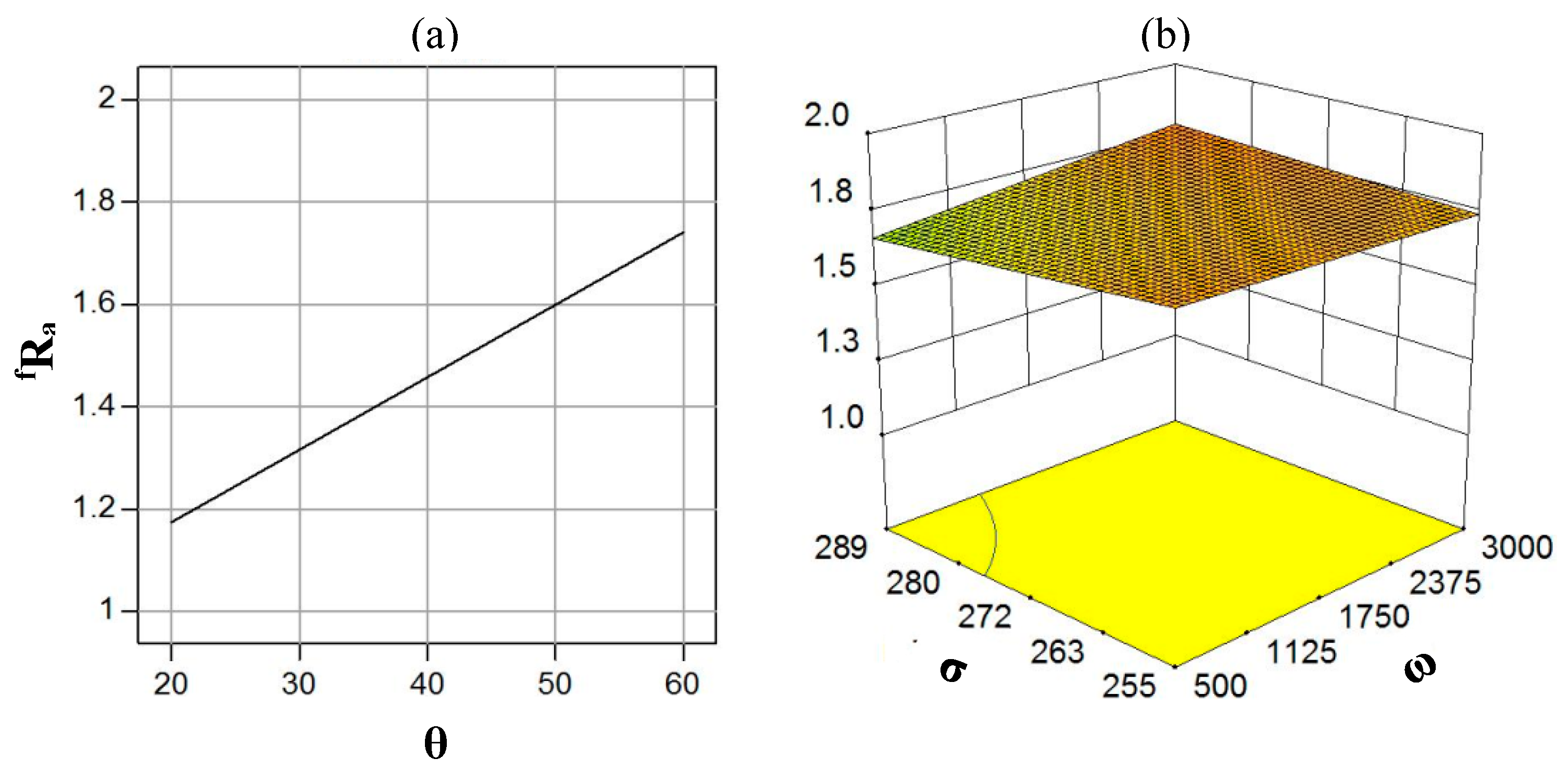

1 Triangle 250 µ inch N9 63 µ meters to 500 µ inch N10125 µ meters 2 Triangles 63 µ inch N7 16 µ meters to 125 µ inch N8 32 µ meters 3 Triangles 8 µ.

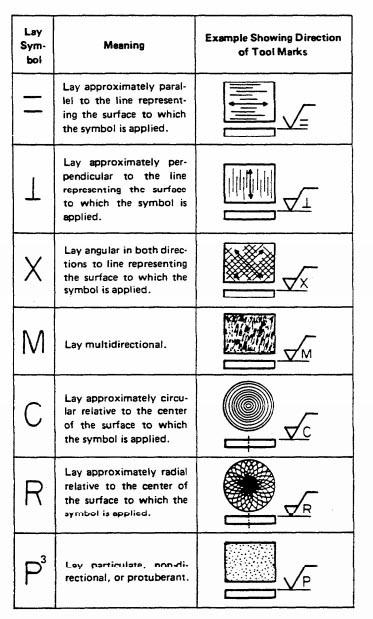

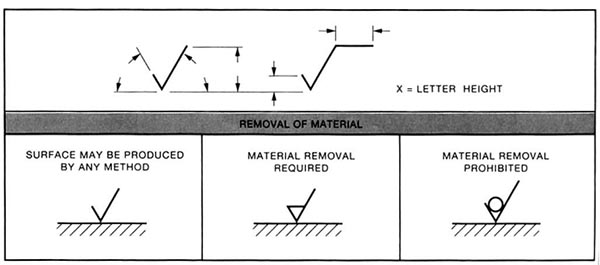

. You can select the face in a part assembly or drawing document. Each surface finishing symbol is used to communicate the surface. There are many variations of the surface texture symbol but most often it is used with a microinch or.

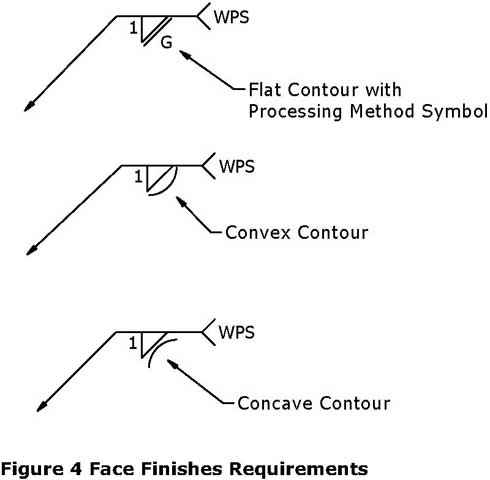

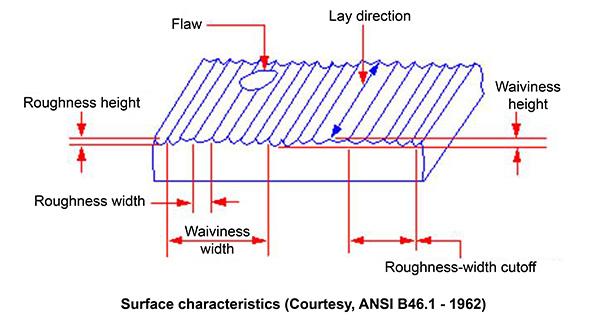

It indicates a surface that requires a material removal process and allowance indicated. In the United States surface finish is usually specified using the ASME. Waviness is not used in iso standards.

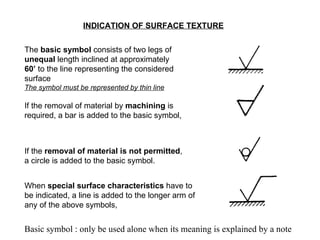

Triangle symbol is a simple way to mark the accuracy. Surface finish symbols are formed by. The ISO surface finish symbols provide a standard way of representing the surface finish of a manufactured component.

You can specify the surface texture of a part face by using a surface finish symbol. This symbol has a bar added to the basic symbol and forms a triangle. In Mechanical Engineering Surface finish and the surface roughness both are referred to same.

Roughness is the most commonly. When you search for machining surface finish symbols on your favorite browser you would notice a range of abbreviations. What is Surface Finish.

A symbol for defining the surface finish of a part. Surface finish refers to a surfaces texture. It indicates a surface that requires a material removal process and allowance indicated.

Roughness is the most commonly specified measured and calculated aspect of surface finish and many people use the term Surface Finish. The chart lists the name of the finish the roughness in microns and the applications. Machining N9 250 63 N10 500 125 Rough Machining N11.

Surface roughness frequently shortened to roughness refers to small irregularities in surface geometry. Surface finish symbols are not the same across. These include Ra Rsk Rq Rku Rz and more.

It is a means of altering material surfaces through processes. These include Ra Rsk Rq Rku Rz and more. Rmax is a roughness parameter that is often used for machining anomalies like scratches and burrs although it may not be as obvious with the Ra surface finish chart.

Surface finish is a parameter that determines the physical characteristics appearance of a component. When professionals refer to surface finish it is often surface. The purpose of a.

Machining symbols and Surface finishMeasuring Surface Roughness Rq Rq is more sensitive to peak and valleys since. But In general Surface finish referred as the overall texture of the surface and it is a. Machining symbols and Surface finish.

Understanding Weld Symbols The Fillet Weld Meyer Tool Mfg

Surface Finishing In Cnc Machining With Symbols Charts Rz Ra Roughness Explanations Standards Mechutopia

What Is Surface Finish Surface Finish Symbol

Surface Finish Texture Symbols Roymech

Surface Roughness Of Engineering Drawing Guru Teknik Mesin

Complete Surface Finish Chart Symbols Roughness Conversion Tables

Indications On Drawings Surface Metrology Guide Digital Surf

Surface Roughness Symbols Iso Finishing

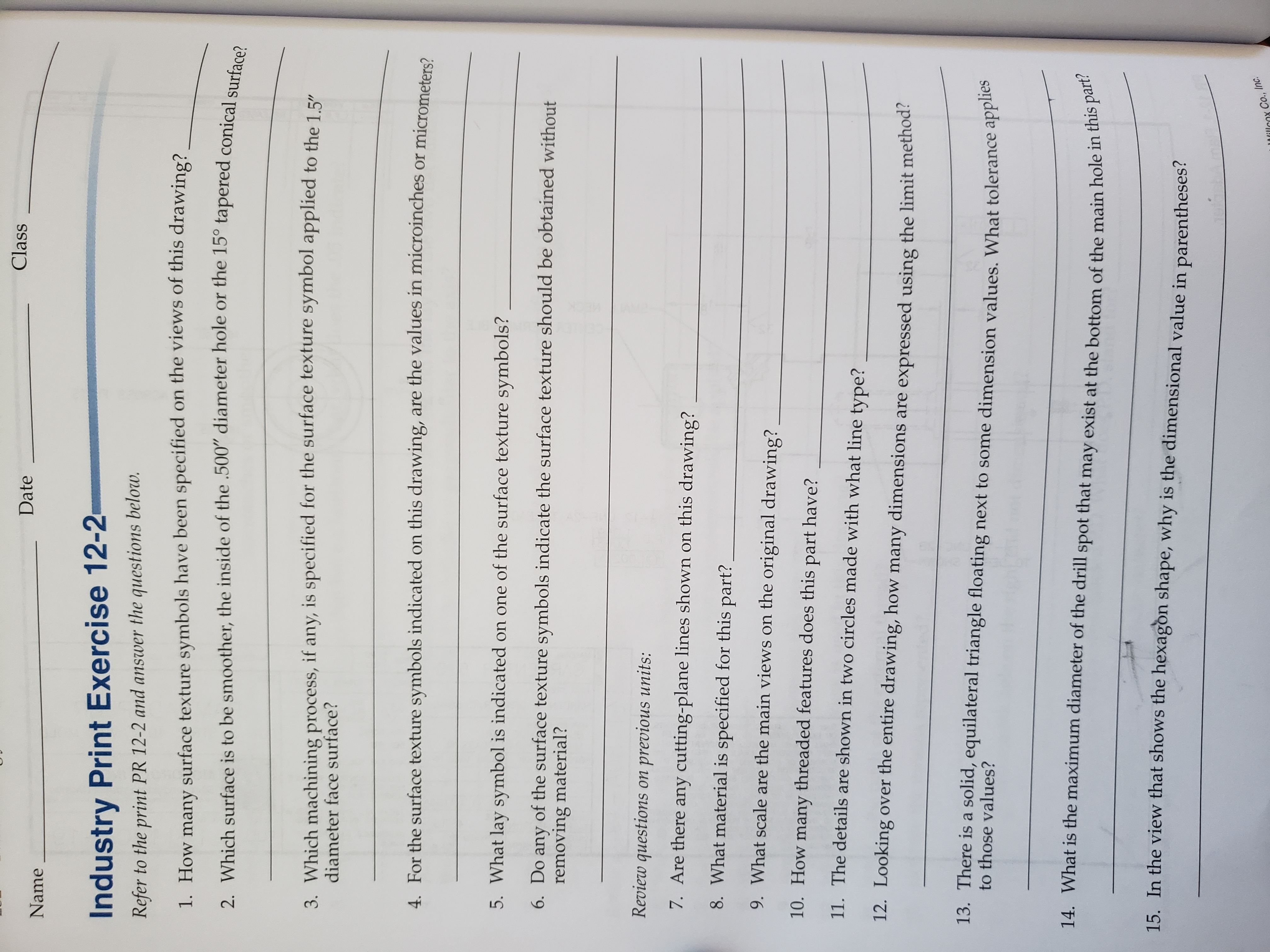

Answered Class Date Name Industry Print Exercise Bartleby

Surface Finish Surface Roughness Symbols Charts Callouts Costs

Metals Free Full Text On The Free Surface Roughness In Incremental Forming Of A Sheet Metal A Study From The Perspective Of Isf Strain Surface Morphology Post Forming Properties And Process Conditions

Complete Surface Finish Chart Symbols Roughness Conversion Tables

Surface Finish Measurement Naman M Dave

Surface Finish Surface Roughness It S Indications Symbols

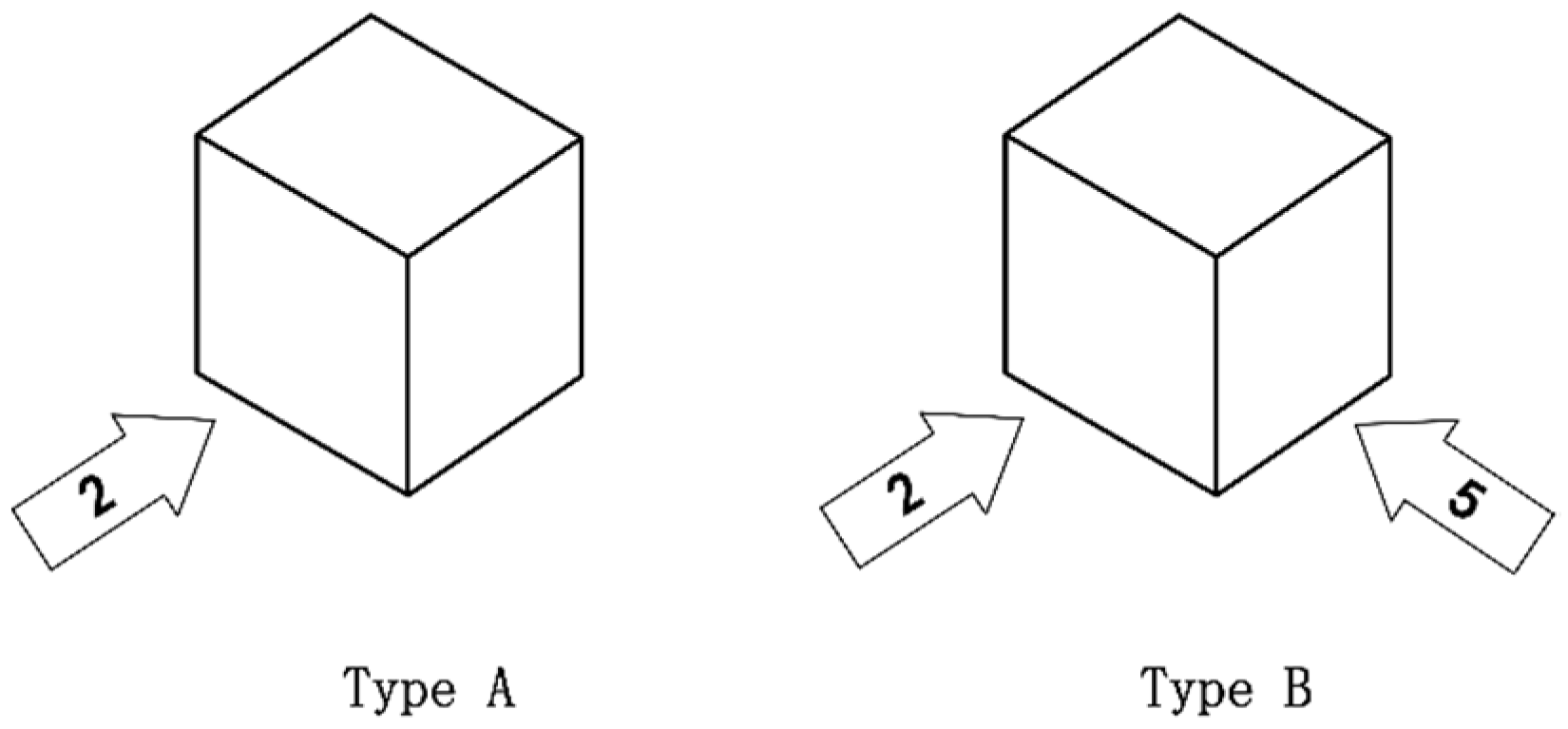

Machines Free Full Text Reconfigurable Machine Tool Design For Box Type Part Families Html

Development Of A Surface Roughness Measurement System Using Reflected Laser Beam Sciencedirect